The current 3-stage treatment process for wastewater consisting of primary, secondary, and tertiary treatment is unable to treat toxic industrial wastewater. The stand-alone AOP treatment technique for colour and odour properties in industrial effluents (dye-based) may be insufficient to meet set government standards and is also limited due to the high cost of AOPs involving continuous supply of chemical reagents. This is because it cannot remove the synthetic industrial dyes and the effervescent colour and odour, which have a long-lasting carcinogenic and toxic effect on the ecological and especially aquatic life. In order to remove this toxicity, an upgraded solution with the Advanced Oxidation Process (AOP) technology is the need of the day.

Working

towards this, researchers from the Indian Institute of Technology, Kanpur with

Malaviya National Institute of Technology, Jaipur and MBM College Jodhpur have

developed a modified AOP solution. This completely modified treatment process

consists of the primary dosing step followed by the sand filtration step,

another AOP and subsequent carbon filtration step. It eliminates the need for

the conventional primary, secondary, and tertiary processes resulting in

maximum colour removal and meets the inland water discharge standards.

Department

of Science and Technology (DST) Government of India (GoI) – Water Technology

Initiative (WTI), along with the Indian National Academy of Engineering (INAE),

supported the development of this technology at a pilot level in collaboration

with Laxmi Textile Prints, Jaipur for the commissioning of this pilot-scale

plant at Textile Industrial Park,

Jaipur.

The

much-improved Advanced Oxidation Process (AOP) technology targeting zero

discharge water management system is being utilized for the complete reuse of

industrial dye wastewater for domestic and industrial usage at a rate of 10

Kilo litres /day. The treatment of toxic and highly carcinogenic industrial

dyes of textile effluents is performed using this AOP technology for degrading

and mineralizing recalcitrant organic matter from effluent wastewater.

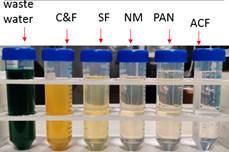

It is a

direct replacement of the existing treatment plant processes and consists of a

low-cost solution of dye adsorption on acid-modified soil followed by a

photochemical reaction step within a photocatalytic visible light filter and a

unique carbon and PAN nano-mat fibre filtration process. Having been set up on

a pilot basis, it remediates industrial wastewater.

The

technology has resulted in the recuperation of 50% of the treatment cost

incurred from conventional processes for water treatment (especially due to the

high cost of sludge disposability) in the water-scarce regions of Rajasthan.

Further, scaling up of this plant to 100 Kilo litres /day capacity to meet the

current industrial requirement is underway with automated plant operation